Transforming Cold Chain Management in Malawi: CIPHER Supports QR Code-Based System Using DHIS2

In recent years, Malawi’s immunization program has faced critical challenges in managing its cold chain equipment (CCE). Outdated, paper-based inventory systems and fragmented data sources—ranging from spreadsheets to handwritten logs—slowed down equipment tracking and maintenance planning, often taking years to compile comprehensive data. Recognizing the urgency to modernize its system, Malawi’s Ministry of Health, through its Digital Health Division, in collaboration with CIPHER, UNICEF, and the Expanded Programme on Immunization (EPI), implemented a QR code-based system using the DHIS2 Tracker platform.

The project aimed to establish real-time, data-driven monitoring of cold chain infrastructure to improve vaccine delivery, reduce equipment downtime, and ensure efficient planning and transparency in Malawi’s immunization program.

A Critical Shift to Digital Inventory

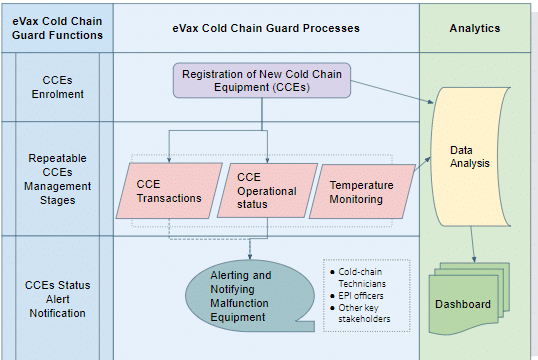

The initiative was born out of a national need to modernize cold chain equipment monitoring in light of recurring public health emergencies, including COVID-19 and disease outbreaks that exposed infrastructure weaknesses. Building on the Ministry’s successful use of DHIS2 for COVID-19 surveillance, the Digital Health Division and partners launched the eVax Cold Chain Guard system within Malawi’s One Health Surveillance Platform.

The system allowed cold chain technicians to register over 600 pieces of equipment across 20 districts in just four weeks using android phones to scan a QR code assigned every individual equipment—an achievement that previously took five years using paper-based methods.

CIPHER’s Role in Implementation

As a key technical support partner, CIPHER (Centre of Innovation for Public Health and Emergency Response) contributed to the rollout and testing of the new system. Working alongside district health teams, the Digital Health Division, and EPI, CIPHER supported:

- Training of cold chain technicians in Lilongwe and Ntchisi, who later mentored peers in 18 other districts

- On-the-ground supervision and problem-solving, especially in facilities facing connectivity issues or mobile device challenges

- Deployment of QR code labels for each piece of equipment, ensuring fast, accurate data entry

- System feedback to refine data fields and workflows based on technician experiences

This hands-on involvement by CIPHER ensured a smooth transition from manual records to a digital, real-time system.

Empowering Field Technicians with Mobile Tools

Using the DHIS2 Android Capture app, technicians in remote areas with poor connectivity were able to collect data offline and sync it later. This flexibility enabled rapid progress, with more than 200 pieces of equipment registered in the first three weeks. QR code labels on each unit allowed instant scanning and updates—reducing errors and improving equipment traceability.

A live messaging group supported by the national team offered real-time troubleshooting and peer collaboration, allowing challenges to be addressed swiftly without interrupting workflow.

Dashboards that Drive Decision-Making

With the new system in place, cold chain managers can now monitor:

- Equipment functionality by district or facility

- Maintenance status and alerts for temperature breaches

- Equipment distribution by funding source or manufacturer

- Capacity vs. actual vaccine storage volumes

These dashboards not only streamline resource allocation but also improve partner transparency, allowing donors such as Gavi, UNICEF, and USAID to track the impact of their contributions and guide future investments.

Testimonies from the Field

“The cold chain equipment management system has helped us access the inventory, track every transaction, and plan the next CCE service.”

– Lucius Future Chisale, Cold Chain Technical Assistant, Central East Zone

“Now, within five minutes, we can log into the system and access all the data we need. It used to take five years.”

– Blessings Kamanga, Product Manager, Digital Health Division

“Data inventory management is now simple, with easy access to models, volumes, and power usage.”

– Anock Sinkhonde, Zonal Cold Chain Technical Assistant, South West Zon